Aquaflame

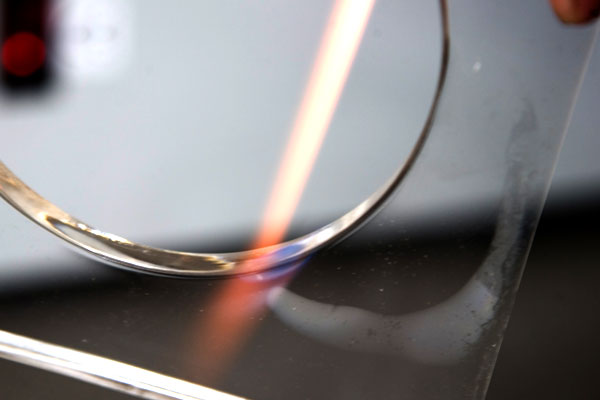

Aquaflame equipment, available in three different power models, provides a solution for flame polishing the edges of acrylic material (PMMA-Plexiglass). The Aquaflame are high performance gas generators, producing a high temperature flame – in the range 1200-3300°C.

Not only that, the Aquaflame is a reliable, low-cost and safe solution as it avoids the management and storage of flammable materials, in fact, gas is produced only during use.

Using a standard power supply, hydrogen and oxygen are produced by the electrolysis of distilled water, in the correct ratio such that hydrogen can be burned in oxygen, thus producing an efficient and highly controllable high-energy heat source.

The only component of this system, in addition to energy, is water. A truly efficient clean and ecological process.

Aquaflame equipment is widely used in the plastics industry for flame polishing transparent thermoplastic acrylic. Acrylic is also known as Plexiglas, Perspex, Poly (methyl methacrylate) PMMA, as well as with the trade names Plexiglas, Acrylite, Lucite, Oroglas, Altuglas, Cryolite Optix and Perspex. After being cut or milled in CNC, it is often necessary to carry out a final polishing of the edge. Aquaflame is ideal for achieving this goal.

| Model | AF500 | AF800 | AF1200 |

|---|---|---|---|

| Gas production (Lt./H) | 75 | 120 | 240 |

| Distilled water use (ML/day) | 30 | 50 | 100 |

| Maximum flame temperature (C°) | 3300 | 3300 | 3300 |

| Electrical usage (kW) | 0.50 | 0.80 | 1.20 |

| Torch tips range supplied | 20-24 | 18-24 | 17-24 |

| Torch tips bore size supplied (Ø) | 0.60-0.31 | 0.90-0.31 | 1.00-0.31 |

| Service recommended period | 4000 hours | 4000 hours | 4000 hours |

| Size (LxPxH) | 400 x 200 x 300 | 400 x 280 x 380 | 440 x 320 x 395 |

| Weight (Kg) | 18 | 33 | 49 |

| Thickness that can be polished in one pass | 5 | 10 | 15 |

| Typical polishing times (minute per meter) | 1 | 2 | 2 |