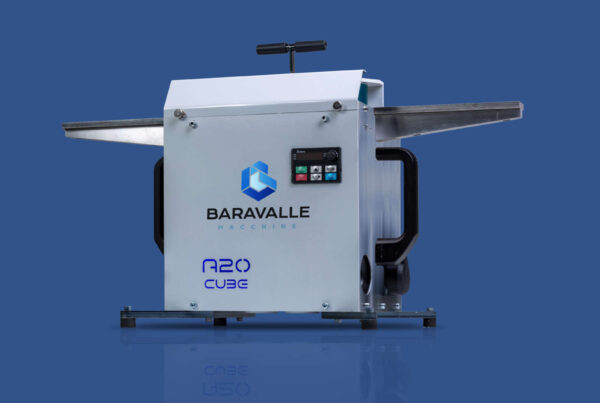

We manufacture machines for processing, polishing and bending plastic materials such as Acrylic (plexiglass), Polycarbonate, Polyethylene, Corian, and PVC

The digital evolution

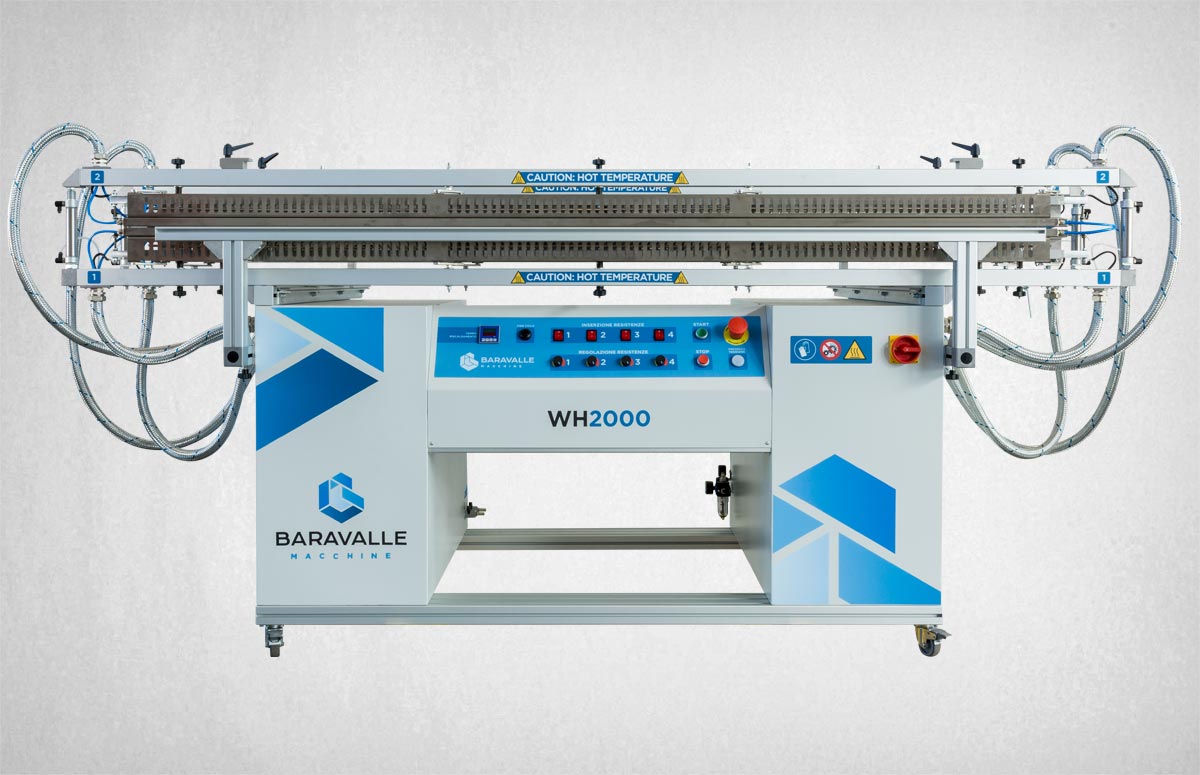

The machines of the QH Series (Quartz Infrared Heaters) and WH Series (Wire Heaters) are now available in their most advanced version: Gen3. Using the Software Controller (PLC), you can operate the machine directly from the touch screen, receive all status information, check temperatures and alarms, save and recall recipes, perform remote maintenance interventions, and much more.

The digital evolution

The machines of the QH Series (Quartz Infrared Heaters) and WH Series (Wire Heaters) are now available in their most advanced version: Gen3. Using the Software Controller (PLC), you can operate the machine directly from the touch screen, receive all status information, check temperatures and alarms, save and recall recipes, perform remote maintenance interventions, and much more.

Greater accuracy in resistance control: each resistor can be adjusted in power percentage (from 0% to 100%) or in temperature (precisely controlling degrees Celsius).

Eco-Mode: if no operations are performed within a specified time period (adjustable), the machine automatically reduces the power of the resistors, allowing for significant energy savings.

The processing parameters (job number, type of material, power or temperature of the resistors, heating time) can be stored and later recalled for repetitive tasks.

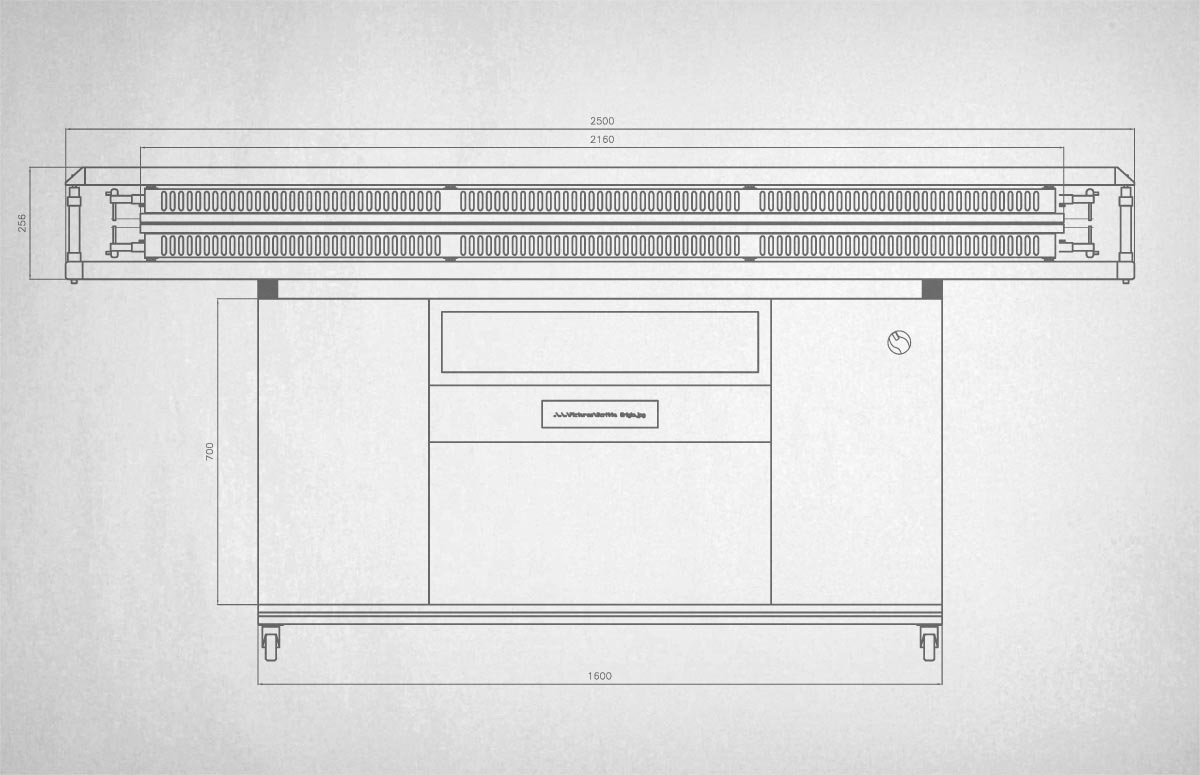

From design

Our plastic bending machines for processing and bending Acrylic sheets, Polycarbonate, Polyethylene, Corian, and PVC, are the result of decades of experience in the field. New ideas give rise to technical drawings.

To machine

From designs we start building and testing. We then adjust the prototypes until we reach the level of ease of use and durability over time.

MACHINES FOR SMALL AND LARGE PRODUCTIONS

Designed to last

The search for the best components available on the market, due to the desire to build machines that last over time, guarantees, for each model, the best we can offer.

User’s satisfaction when operating the machineries is what matters most to us. For this reason we kindly ask you to provide us with your experiences of use and your advice.

Help us to improve our service

After-sales assistance

24/7 throughout Italy and worldwide

We believe that the added value lies in guaranteeing constant assistance to our customers. Conscious of how exorbitant a machine stop can be, we are always active to reduce the resolution time of every problem.

If you have any questions, you can contact us directly, we will be happy to provide you with our assistance policies.

Phone +39 0172 691823

Efficiency and precision

Passion for experimentation and experience are at the base of all our machines

Experience

We have been manufacturing machines for a lifetime, and we have “played” with electricity in all its forms.

Passion

The greatest satisfaction comes when, after experiencing something for days, suddenly everything falls into place.

Precision

The correct processing of thermoplastic materials is ensured by the perfect balance between the forces involved.

Strength

Our machines are made to last. We choose the individual components among the top of the range available on the market.